The seats in molded foam are more popular and fit for various locations such as offices, hotels, cafes, restaurants etc. Interiors designers are much more willing to select the molded foam design for the premium inter projects.

The relaxing feeling of being perfectly wrapped and supported when sitting deeply in a chair after a long period of work. Where does this comfort come from?

——A seating made of PU mold foam

When it comes to creating comfortable, durable, and versatile seating, the material inside the chair is as important as its design. Chair inserts, especially those made from Molded foam, play a crucial role in ensuring seating comfort and performance. In this article, we explore the key advantages of foam chair inserts and their the production process.

Why Molded Foam Matters ?

The molded foam interior of the chair is crafted for durability and superior performance. Unlike traditional cushioning materials, molded foam retains its shape over time, ensuring consistent support. Its contoured design adapts to your body, relieving pressure points and reducing

discomfort during extended work sessions.

What is Molded Foam ?

Molded foam is a versatile material made from polymeric substances that create an open-cell structure, making it lightweight and flexible. This foam can be tailored to meet specific requirements, such as varying densities, hardness levels, and fire-retardant properties. It’s a popular choice for chair inserts because it balances performance, comfort, and affordability.

Unlike the instantaneous rebound of ordinary sponges, the characteristic of PU molded foam lies in its slow deformation recovery process. This slow rebound feature enables it to perfectly fit the human body’s curves and evenly distribute pressure.

Benefits of Foam in Chair Inserts

1.Enhanced Comfort

Molded foam is celebrated for its ability to provide excellent support and comfort. It conforms to the user’s body shape, distributing weight evenly and reducing pressure points. This makes it ideal for ergonomic office chairs, automotive seats, and healthcare seating.

2.Supportive Structure

High-density foams deliver optimal support, maintaining posture and reducing strain on the body over extended periods.

3.Durability

Quality foams are resilient and resistant to sagging, ensuring the longevity of chairs even with frequent use.

4.Versatility in Design

Molded foam can be molded into virtually any shape, making it suitable for a wide range of chair designs. Whether it’s a sleek office chair or a luxurious armchair, foam inserts adapt to meet aesthetic and functional requirements.

5.Lightweight Material

Foam inserts are lightweight, making them easier to handle and integrate into chair designs without compromising on strength.

6.Cost-Efficiency

The durability and performance of foam make it a cost-effective solution for manufacturers and consumers alike.

Molded

foam molding

Molded foam owes its superior comfort and durability to an innovative manufacturing process. Liquid foam is poured into precision molds, where it solidifies into a dense, contoured shape tailored for ergonomic support. This method ensures consistent structure and performance, setting molded foam apart from other cushioning material.

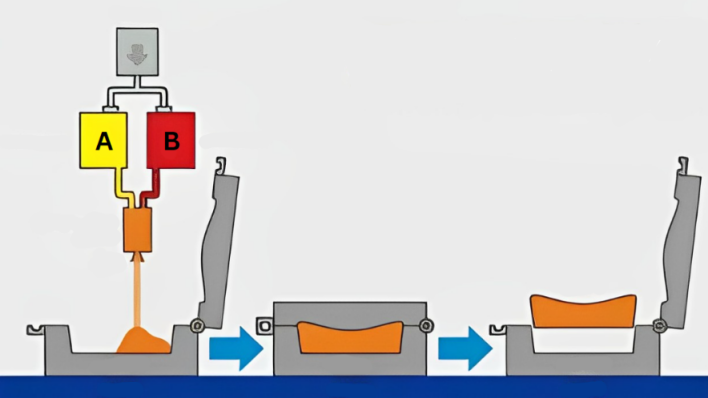

Step-by-Step Molded Injection Molding Process

Material Preparation: Molded resin is mixed with catalysts and colorants before being loaded into the injection molding machine. First, apply a release agent to the mold,then attach the prepared built-in shelf. Our company usually uses 10mm diameter iron pipes to have a stronger inner structure.

And the raw materials are pure without adding powder to make sure its flexibility and elasticity. If you have a chance to see the foam under the fabric, you will easily see whether is good or not by checking whether it is rough, bumpy, shortage of materials in some where. See below compared photo:

Injection: The molten Molded is injected into a mold under high pressure, filling the cavity with the resin.

Cooling and Solidification: Once the mold is filled, the material cools and solidifies, taking the shape of the mold. This process will take approximately 10 to 15 minutes.

Understanding the process, we would like to let you know the inject machine also plays a key role for a good molded foam, a good machine will have a good pressure, stable temperature control, even material stirring and digital operation to avoid manual mistakes.

Ejection: After cooling, the mold is opened, and the finished part is ejected. But this is not the end. Further cutting, polishing, and finally a final shaping are required to produce a PU mold foam product.

Although machines and raw materials are the key factors in making the PU mold foam, the proportion of materials, the control of temperature, and the management of time are also tests of the experience of the operators. We have a master who has been focusing on molded foam for more than 20 years, he knows how to make the material proportion, how to settle the suitable temperature in different whether, how to improve the foam shape, how to adjust the mold to achieve a good design with the best comfortable sitting experience. And the master can design the hardness of the foam by adjust the material prescription, if the furniture designer would like to make it softer or harder, we can do that.

We even can make another piece of molded foam for the back and seat to increase the fit and comfort according to different customer’s requirements for a premium commercial projects.

Conclusion

Molded foam has become a cornerstone of modern furniture and seat design, offering unmatched comfort, support, and durability. Chairs built with molded foam can elevate both functionality and style, making it a must-have for any space.

Besides supplying the complete chairs, we aslo supply the molded foam only. The customers can buy the molded foam as parts of the chair, the base, the fabric, then do the assembly at their factories.

Ready to experience the difference? Explore Our Chair Collection or Contact Us today. (这段话超链接到某款定型棉产品上)